Local vs Long Hauling

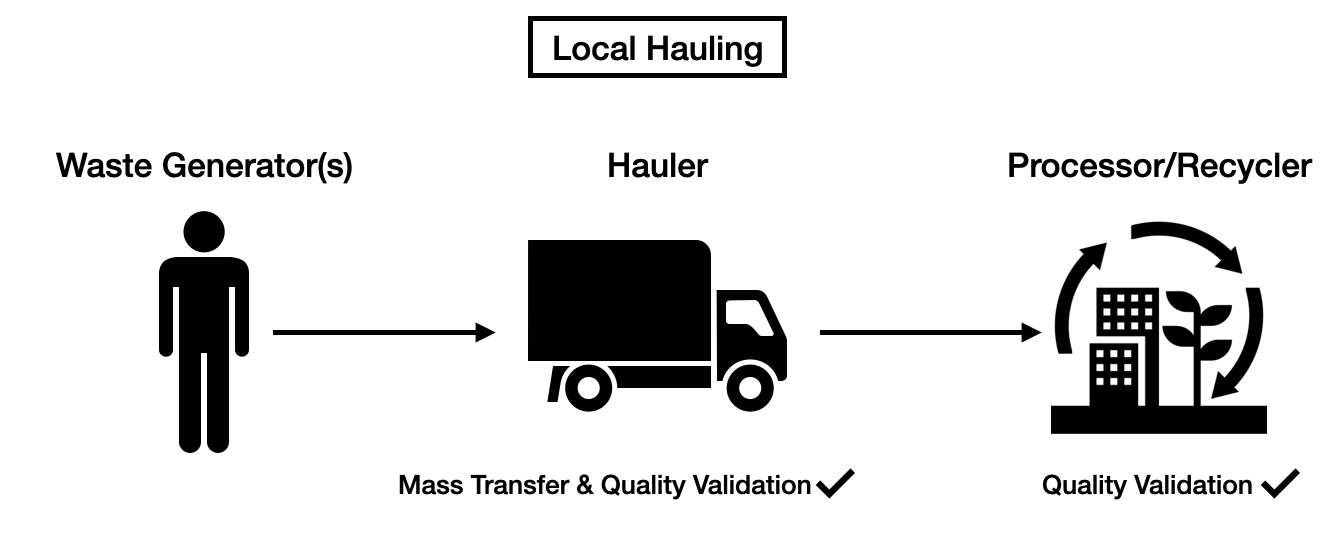

Logistics operations are often referred to as either local hauling or long hauling. For local hauling routes, haulers typically execute multiple Pick-up service orders (going door-to-door,) validating the waste that is collected, before arriving at a Processor, who will then execute a Drop-off service order to validate the contents of what is being delivered.

In the transfer of the waste between the Generator and the Hauler, there is a Pick-Up Service Order and in the transfer of the waste between the Generator and the Processor there is a Drop-Off Service Order (SO).

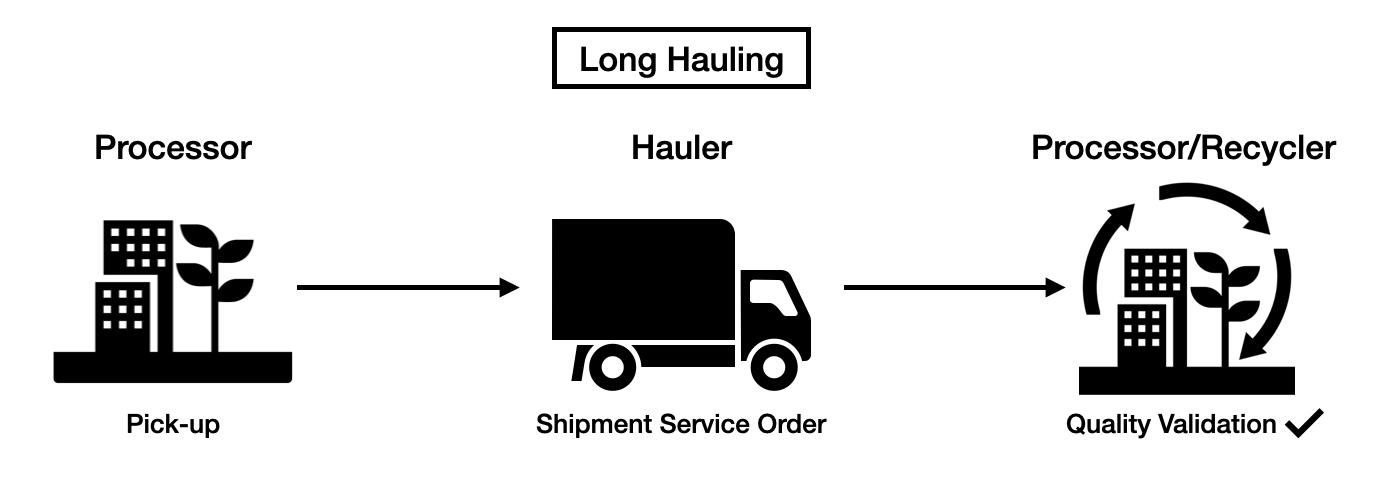

In long hauling, material mass is picked up at a Processor and dropped off at another Processor or Recycler. Material transfer is recorded in a Shipment SO that includes both pick-up and drop-off information in the same service order, but waste is validated only by the Processor or Recycler who is receiving the material.

While there are many roles in the supply chain of waste, participants often take on more than one role. For example, a Hauler can also be a Processor if the company picks up waste and takes it to its own processing facility. A Waste Generator who takes waste to a Processor is both a Waste Generator and a Hauler. A Waste Generator who contracts hauling services to pick up its bins is both the Waste Generator and the Source Bin Custodian. These roles are important to have identified as they are the mechanism through which recycling contribution rewards in the form of stable coins, such as $USDC or $CARROT tokens, are later distributed to each participant recorded in a certified-recycled MassID.

Let’s expand on one of these examples to deepen our understanding. Municipalities, companies, and non-governmental organizations can sponsor, organize and operate independent bin networks to be accessed by private customers (as in the case of Ecozinha described above) or by the public at large, in distributed drop-off sites. In such cases, a Bin deposit entry (SO) is a record of a material mass dropped off by a Waste Generator at an identified third-party bin. The Bin Custodian is the Validator of waste mass and responsible for quality controls for its bin, even if this is a passive practice that is later corroborated by a Hauler performing the task of a Validator in the next step of the supply chain.

The role of the Recycler is also critical to understand. A Recycler is, by definition, a Processor, but with the added distinction that the organization performs the actual work of recycling for a specific waste material type. This distinction is verified and homologated by third party Auditors. For example, a glass bottling plant that utilizes cullet in its furnaces to make new bottles is a Processor and cullet Recycler. It cannot recycle plastic. A composting facility that transforms food waste into compost for use in agriculture is a compost Processor and food waste Recycler. It cannot recycle electronic waste. As Processors validate waste recycling for a mass type for which they are an homologated recycler, the MassIDs become available to credentialed Carrot Protocol Auditors to be further validated and tokenized into recycling credits as TRCs (Tokenized Recycling Credits) and/or TCCs (Tokenized Carbon Credits.) For TRC and TCC distribution purposes it is important to note that Recyclers get attributed two Participant roles in each MassID. They perform the work of receiving waste and sorting as a Processor, and for recycling as a Recycler.

Last updated