MassID Splits

Changes to MassIDs occur through the audit and validation process when waste arrives at a recycling center both in local hauling and long hauling situations. The Validator at a Processor will analyze waste materials and audit mass types and amounts.

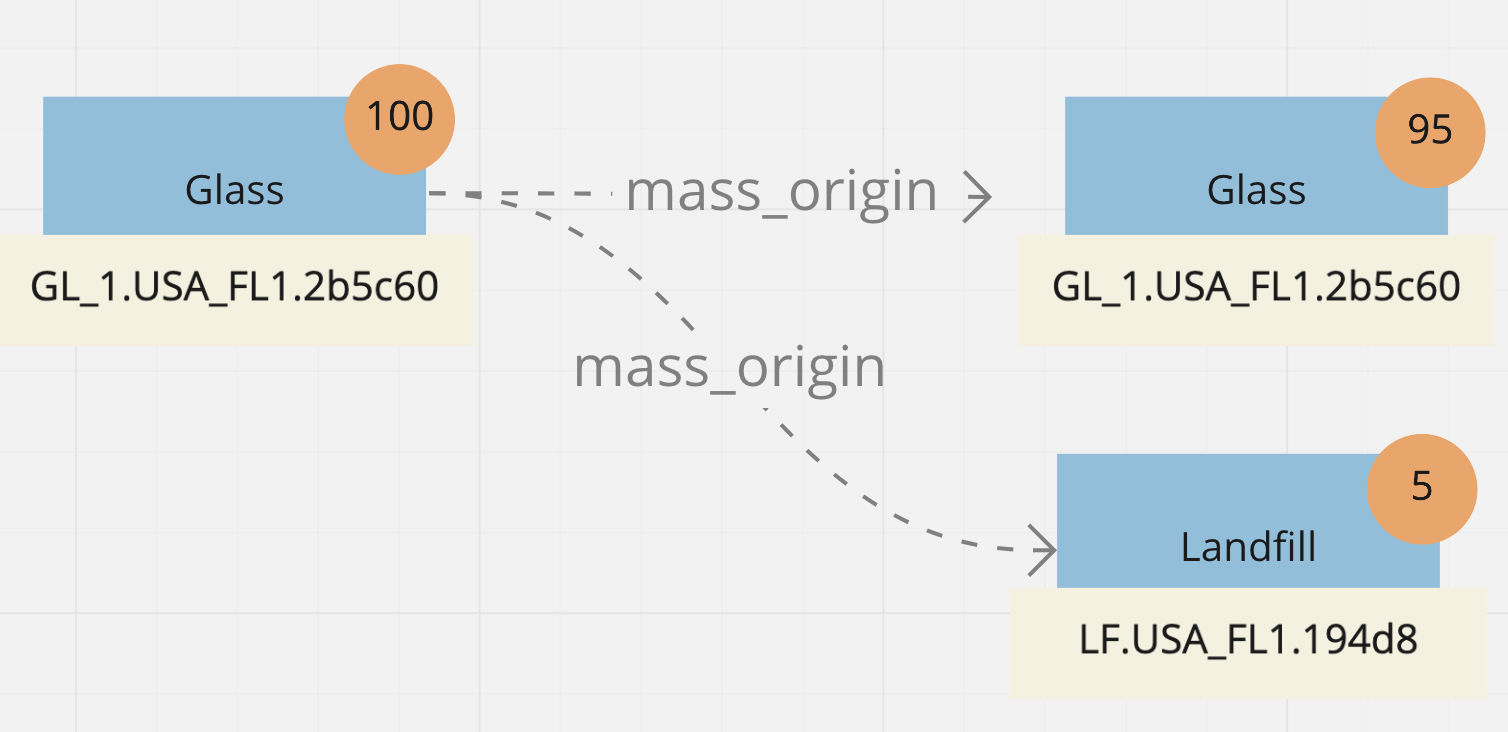

Let’s take a look at an example where a glass MassID weighing 100kg arrives at a glass bottling plant. Upon arrival the Validator at the Processor identifies that 5 kg of non-recyclable waste is mixed with the cullet, and once removed from the cullet heap it will need to be sent to a landfill. The original MassID will have its weight reduced by 5 kgs and a new Landfill MassID of 5 kgs will be created.

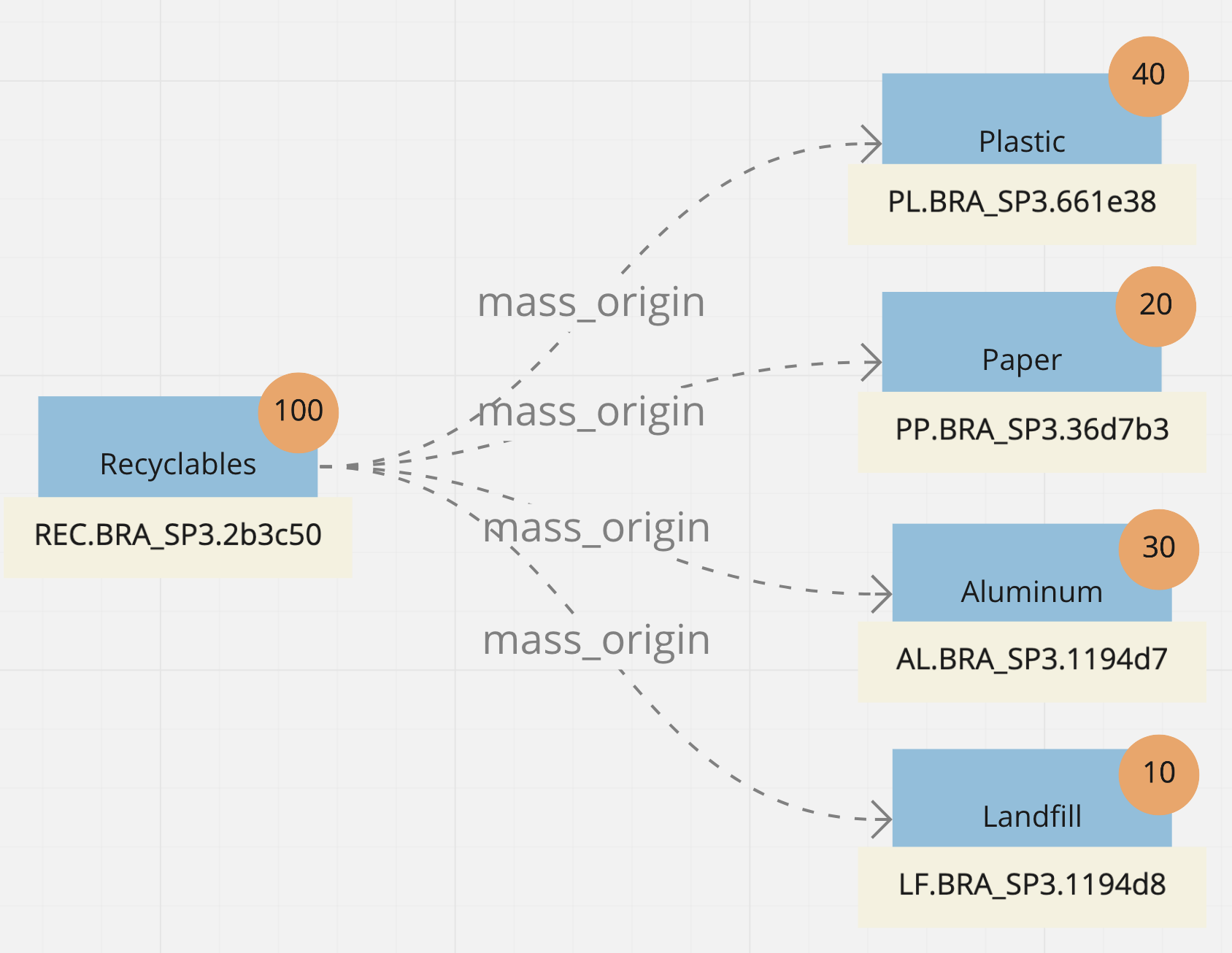

MassIDs can also originate in an aggregated waste unit, before getting broken down by material mass type. The most common example is when a MassID is born from a pick-up of commingled recycling, in other words: Plastic, Paper, Aluminum, etc. Let’s take a look at an example of commingled recycling pick-up in Brazil’s São Paulo state in the Municipality identified as number 3. The aggregated waste unit ceases to exist as it gets sorted into different material mass types, each with its own weight. However, the chain of custody is preserved on the blockchain.

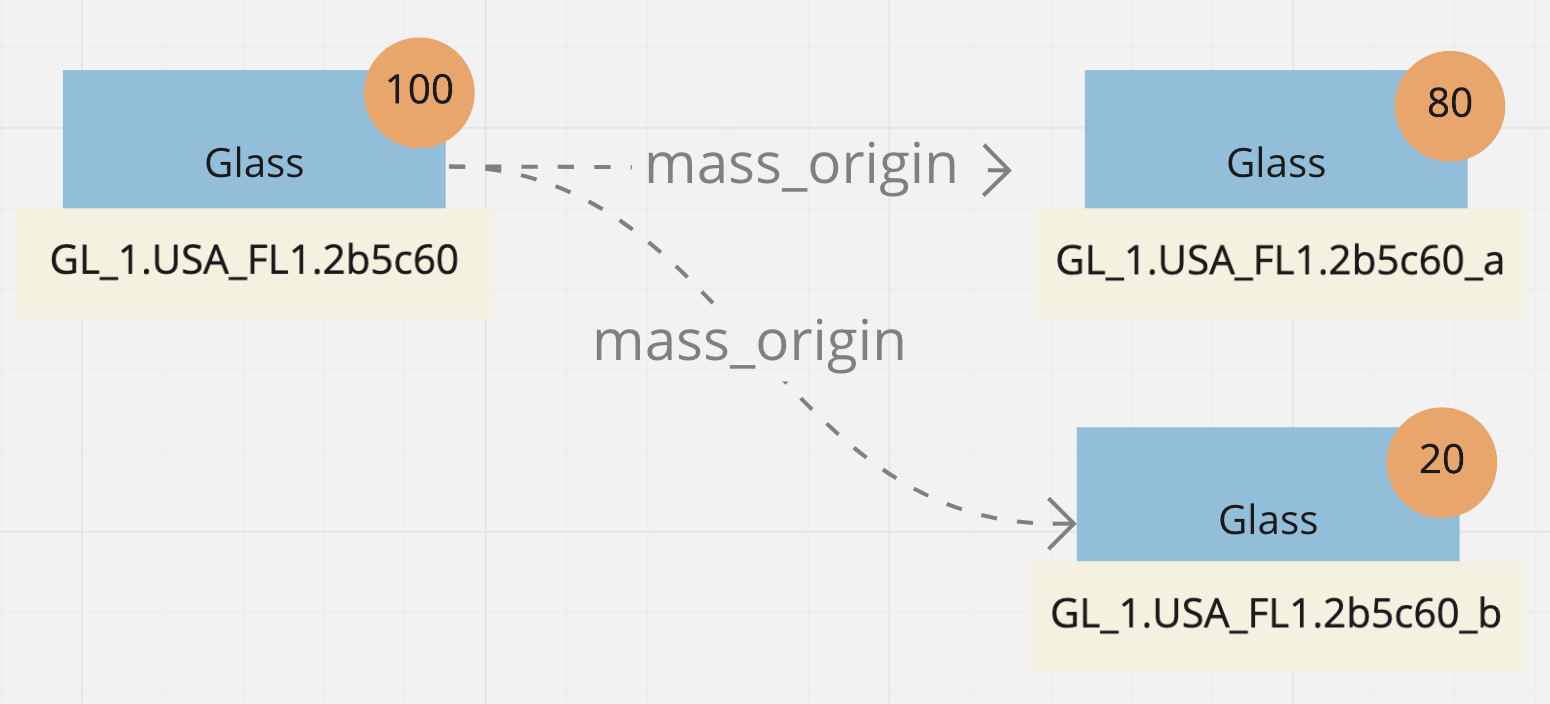

Next, in a Shipment Order, a MassID can undergo a split to accurately fill a mass transfer from one Processor to another. The waste weight audited by the Validator at the Processor triggers the transfer of MassIDs on a First-In-First-Out (FIFO) basis and the split amount required for the final MassID. Below is an example when the required mass amount to fill the transfer package is 80 kgs. A 100 kg MassID is split into 80 kgs and 20 kgs units.

The same occurs when forming Tokenized Recycling Credits (TRCs) of 1 ton units. The final MassID in the FIFO order at the Recycler is split to complete a package of IDs that is inserted into a TRC or TCC.

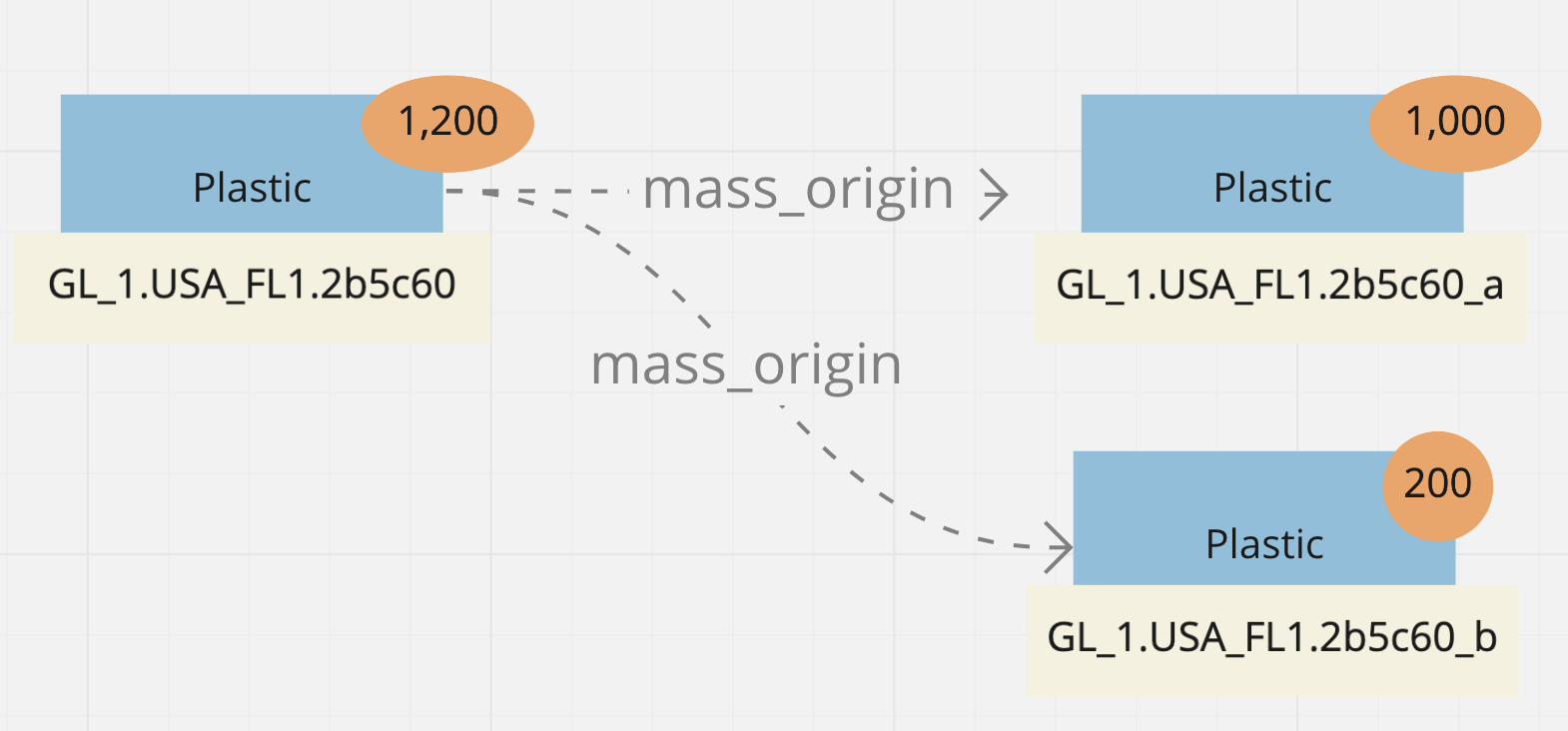

On the other hand, when a MassID is larger than 1 Ton (1000 Kgs) it becomes too large to fill a TRC, which by definition has 1,000 Kgs. It must, therefore, be split before it can be packaged into a TRC.

Last updated